Steel Framing: The Future of Homes

Engineered strength, fire resistance, and lasting value built for Hawaii & California

What is Steel Framing?

Steel framing, utilizing precision-engineered cold-formed steel (CFS) components, is the next generation of building, offering superior durability and structural integrity over traditional wood lumber. These manufactured studs, joists and trusses are galvanized with a protective zinc coating to prevent corrosion, providing unmatched longevity, exceptional structural performance, and a significant upgrade in modern construction.

Key Technical Specifications

Material: 20-gauge galvanized steel (minimum) ensuring robust load-bearing capability.

Yield Strength: 50,000 PSI (vs. wood at 1,200 PSI) — a 40x improvement in strength-to-weight ratio for a safer, stronger structure.

Thermal Expansion: Minimal thermal expansion coefficient means no warping, shrinking, or splitting over time, keeping walls straight and finishes pristine.

Fire Rating: Non-combustible (Class A Fire Resistance). Significantly reduces the spread of fire, offering superior protection for occupants and assets.

Emphasize Durability and Peace of Mind (Benefit-Oriented)

In practical terms, these characteristics mean the steel structure is resistant to fire, corrosion, and dimensional changes, guaranteeing a home that is straight, safe, and maintenance-free for decades. This is the foundation of modern durability.

The Science Behind Steel's Superiority

Stronger materials. Smarter construction

Structural Engineering Advantages

Steel's molecular structure provides exceptional strength-to-weight ratio. While wood fibers can compress and fail under load, steel maintains its structural integrity through:

Uniform material properties - No knots, warping, or grain inconsistencies

Predictable load distribution - Engineers can calculate exact load paths

Elastic deformation - Steel bends under extreme loads but returns to original shape

Fatigue resistance - Maintains strength through repeated stress cycles

Weather Resistance Science

Steel framing's galvanized coating creates a metallurgical bond that provides:

Sacrificial protection - Zinc coating corrodes before steel substrate

Self-healing properties - Minor scratches seal themselves through zinc migration

Humidity resistance - No organic material for mold or rot growth

Thermal stability - Maintains strength from -40°F to 1200°F

Quantified Benefits for Your Investment

Stronger performance, lower risks, and long-term financial savings you can count on

Structural perfoemance

25x stronger tensile strength than wood (50,000 PSI vs 2,000 PSI)

Spans 40% longer without support beams

Zero shrinkage - maintains exact dimensions permanently

200+ mph wind resistance when properly engineered

Construction Efficiency

60% faster framing - pre-cut components eliminate measuring/cutting

Weather independent - installation continues in rain/wind

Precision fit - components manufactured to 1/16" tolerance

Reduced labor - lighter weight, easier handling

Risk Mitigation

100% termite proof - no organic material to consume

Fire resistant - won't ignite, contribute fuel, or emit toxic gases

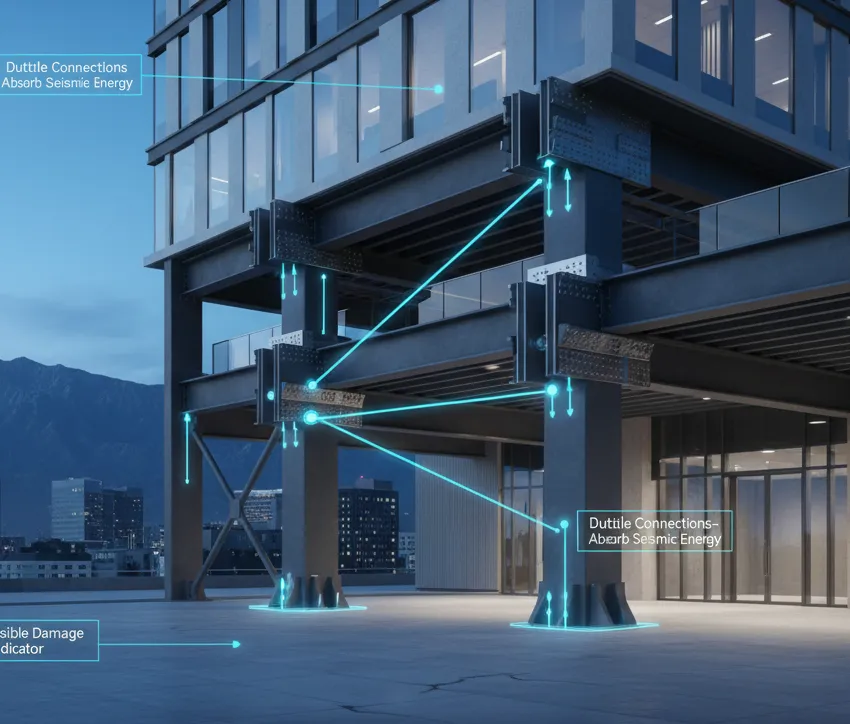

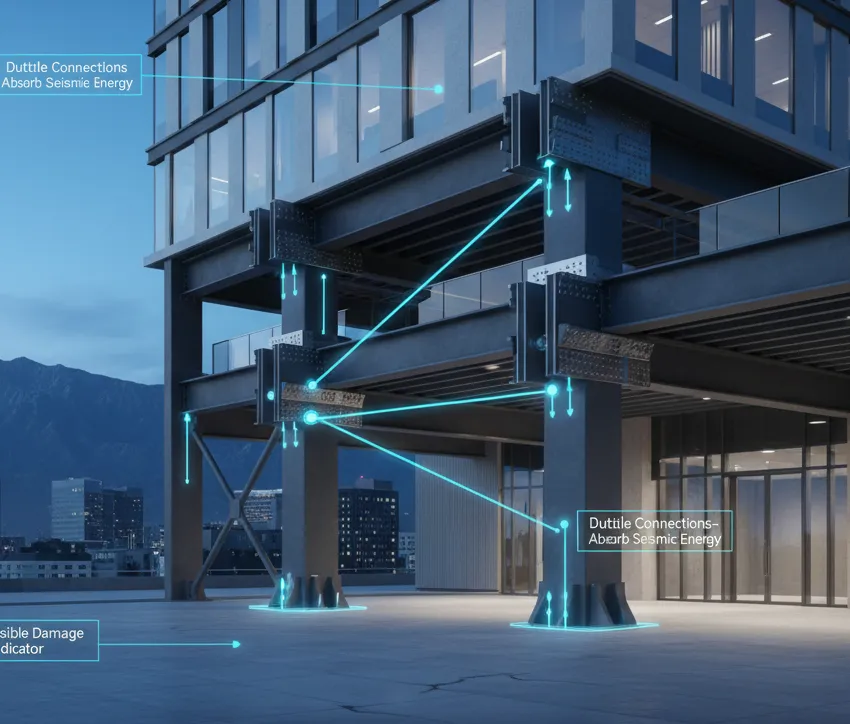

Seismic performance - ductile connections absorb earthquake energy

Insurance savings - 15-30% premium reduction typical

Financial Returns

60% faster framing - pre-cut components eliminate measuring/cutting

Weather independent - installation continues in rain/wind

Precision fit - components manufactured to 1/16" tolerance

Reduced labor - lighter weight, easier handling

Steel vs. Wood: The Technical Comparison

Performance Factor

Tensile Strength

Dimensional Stability

Fire Resistance

Pest Immunity

Moisture Response

Lifespan

Recycling

Steel Framing

50,000 PSI

Zero movement

Non-combustible

100% termite proof

Unaffected

100+ years

100% recyclable

Wood Framing

2,000 PSI

3-5% shrinkage

Highlyflammable

Bug Vulnerable

Swells, warps, rots

50-75 years

Limited reuse

Advantage

25x stronger

100% stable

Complete protection

Total immunity

No degradation

40% longer life

Fully sustainable

Why Steel Framing is Essential in Hawaii & California

Engineered to withstand pests, humidity, earthquakes, and wildfires.

Hurricane Protection

Hawaii's hurricane seasons demand superior structural integrity. Steel framing provides:

Engineered wind uplift resistance up to 200+ mph

Continuous load path from foundation to roof

No organic failure points that compromise structural integrity during storms

Wildfire Defense

California's fire risk requires non-combustible construction. Steel framing offers:

Class A fire rating - highest fire resistance classification

No fuel contribution - steel won't ignite or spread flames

Structural integrity maintenance even under extreme heat exposure

Wildfire Defense

California's fire risk requires non-combustible construction. Steel framing offers:

Class A fire rating - highest fire resistance classification

No fuel contribution - steel won't ignite or spread flames

Structural integrity maintenance even under extreme heat exposure

Seismic Performance

Both regions face earthquake risk requiring flexible, strong structures. Steel provides:

Class A fire rating - highest fire resistance classification

No fuel contribution - steel won't ignite or spread flames

Structural integrity maintenance even under extreme heat exposure

The Qoterie Steel Framing Process

1. PRECISION ENGINEERING (Week 1)

Advanced 3D modeling creates exact specifications for your steel frame components, ensuring perfect fit and optimal structural performance.

2. FACTORY FABRICATION (Week 2-3)

2. FACTORY FABRICATION

(Week 2-3)

Components are manufactured in controlled conditions with computerized cutting and forming equipment, guaranteeing precision and quality.

3. RAPID ASSEMBLY (Week 4-5)

Certified steel framing specialists assemble your structure using specialized tools and techniques, completing framing 60% faster than wood.

4. QUALITY VERIFICATION (Ongoing)

4. QUALITY VERIFICATION (Ongoing)

Every connection undergoes inspection to ensure compliance with engineering specifications and building codes.

The Qoterie Steel Framing Process

1. PRECISION ENGINEERING

(Week 1)

Advanced 3D modeling creates exact specifications for your steel frame components, ensuring perfect fit and optimal structural performance.

2. FACTORY FABRICATION (Week 2-3)

2. FACTORY FABRICATION

(Week 2-3)

Components are manufactured in controlled conditions with computerized cutting and forming equipment, guaranteeing precision and quality.

3. RAPID ASSEMBLY

(Week 4-5)

Certified steel framing specialists assemble your structure using specialized tools and techniques, completing framing 60% faster than wood.

4. QUALITY VERIFICATION (Ongoing)

4. QUALITY VERIFICATION (Ongoing)

Every connection undergoes inspection to ensure compliance with engineering specifications and building codes.

Investment Analysis: Steel Framing ROI

Initial Premium: Steel framing typically costs 15-20% more than wood framing upfront.

Annual Savings:

Insurance reduction: $2,400/year (average luxury home)

Maintenance savings: $1,800/year (no rot, pest, or settling repairs)

Energy efficiency: $600/year (superior thermal performance)

Total annual savings: $4,800/year